Product Description:

PIR (polyisocyanurate foam) panels are the latest generation insulation panels, with better quality and performance and lower production cost. They are becoming more and more popular and widely used for cold rooms, processing rooms and cold storage projects, etc.

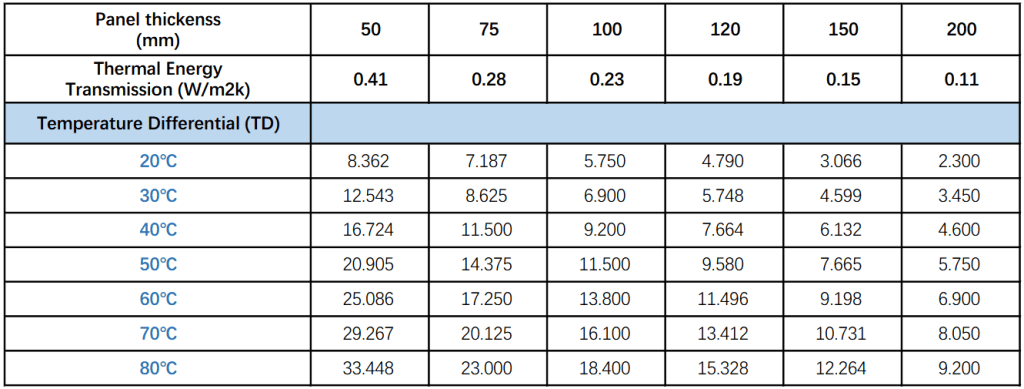

1# Thermal energy transmission (W/m2K)

The maximum heat gain by conduction in a cold room should be limited to 10 W/m2. This table shows the optimum insulation thickness to be selected for various temperature differentials (TD).

2-1# Core Density

Density is very important to ensure the above mentioned thermal energy transmission. The best density is 42kg/m3, which we can promise you. But it is a pity that some suppliers only use 35kg/m3 or 32kg/m3 density, which results in poor performance of these panels.

How to Test

Press your fingers on the foam and feel the density. If your fingers could destroy it and fall on the foam, then its density would not be 42kg/m3.

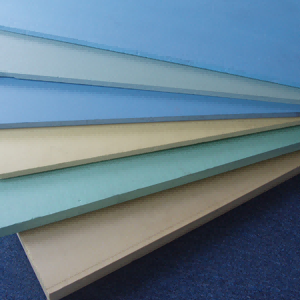

Below are two different PIR panels, with different densities.

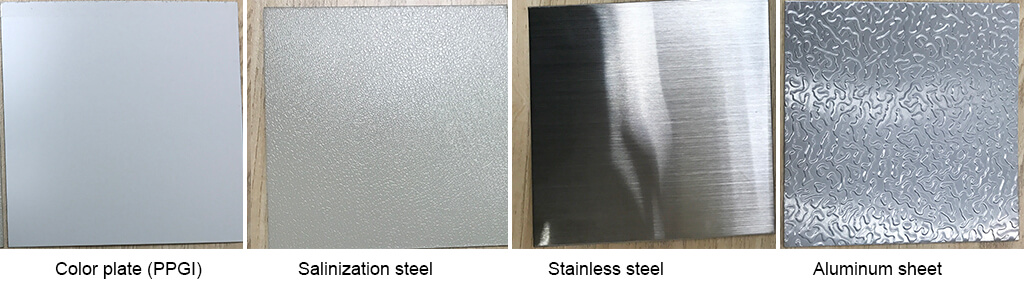

2-2# Steel

We could offer different kinds of steel, each with different characteristics. For each kind of steel, we could offer different colors and textures, etc.

2-3# Fireproof Grade

If we cut the PIR foam and do a fire test, the B2 fire rating releases more smoke and might catch fire, but the B1 fire rating has better performance, which means it releases less smoke and won’t catch fire.

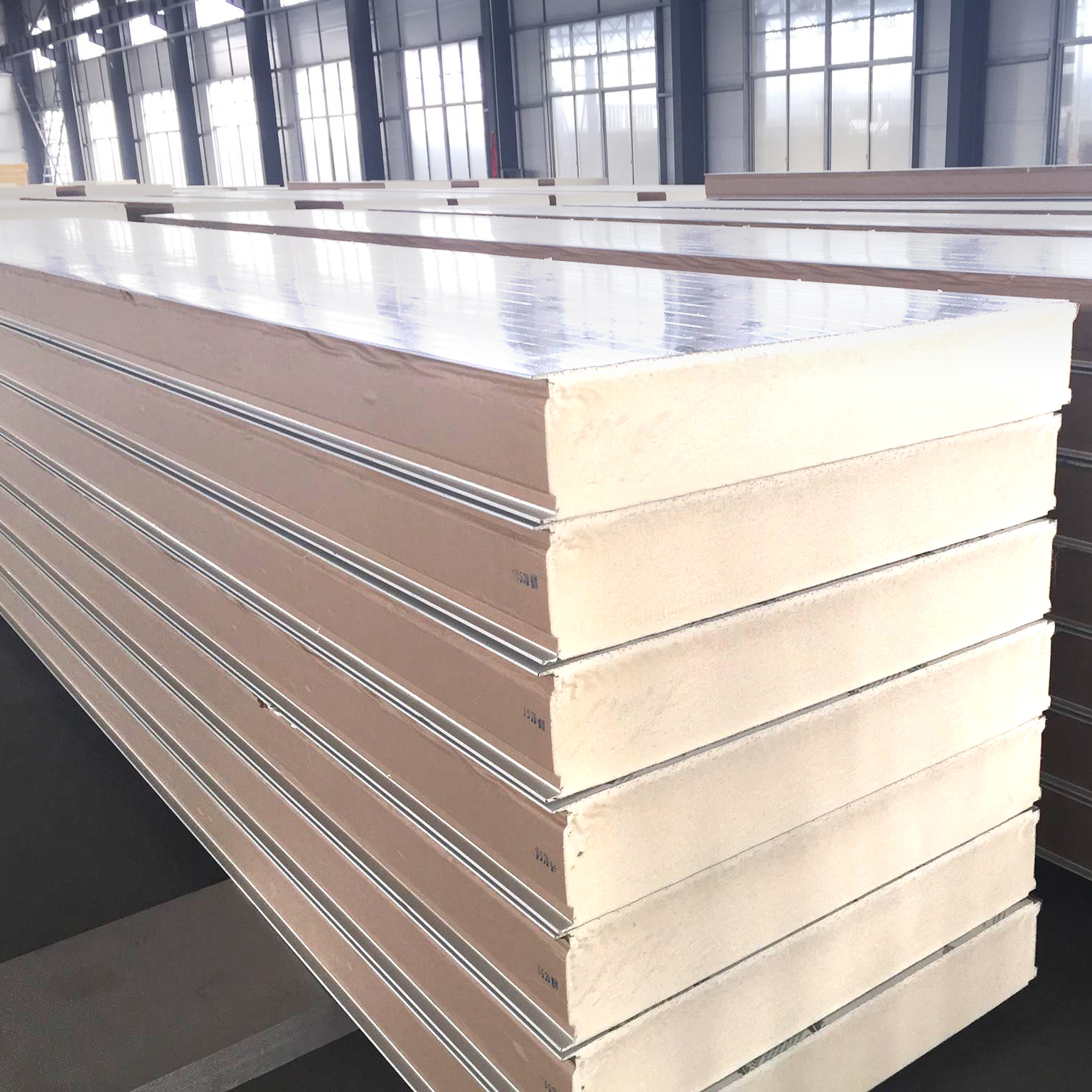

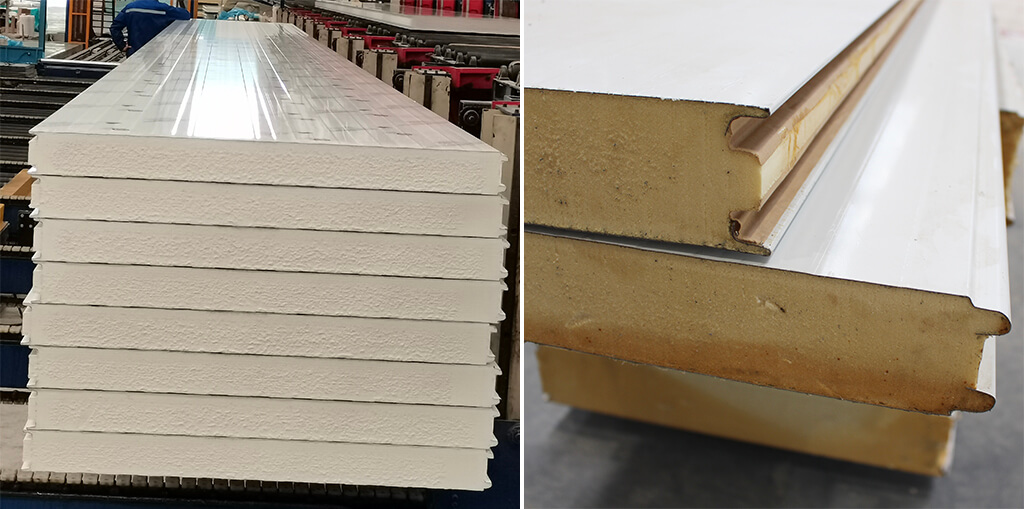

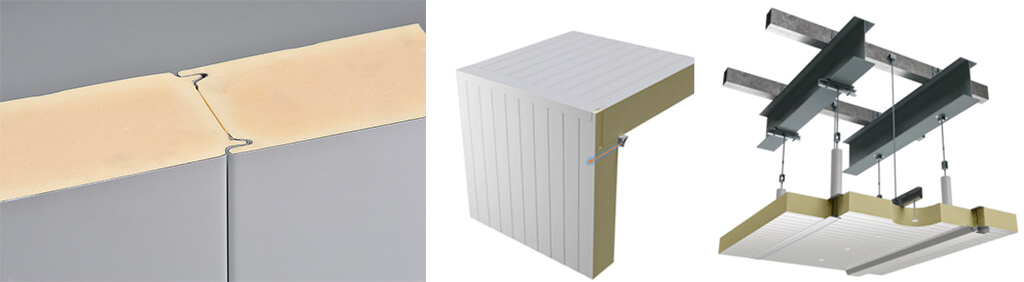

3# More photos

For our PIR panels, each piece is of high quality and with good joints.

5# Our production lines:

Modern factory with 4S quality management standards. More than 20 years of experience in refrigeration and insulation panels.

5# Project cases

6# Visiting clients